Electrical System Topics

The 48 Volt system is a mild hybrid system introduced to give the benefits of a high voltage system without the additional health and safety concerns of such systems which operate at high voltage. The safety cut-off voltage for special considerations and precautions, such as contact protection and insulation control is in excess of 60 Volts. It is supplementary to the standard 12 volt system that is universally used. Some manufacturers favor vehicles fitted with an Integrated Starter Generator (ISG), which can assist the internal combustion engine during acceleration and high loads. The ISG is located between the internal combustion engine and the transmission. Many manufacturers use an electric supercharger also to increase engine power output even further. The ISG can harvest kinetic energy under over-run conditions to charge the high voltage Lithium ion battery.

The ISG is a brushless DC motor that requires position sensors on all three phases for correct commutation.

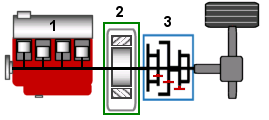

Internal Combustion Engine.

Integrated Starter Generator.

Transmission.

The engine water pump and air conditioning compressor can be operated via the 48V system, this allows for seamless transition within the cabin when the stop/start system is activated. This also makes the engine drive-belt redundant, further increasing the efficiency of the engine by reducing losses.

Other manufacturers have implemented a belt-driven starter/alternator which can be classified as a synchronous machine similar to a conventional alternator or an asynchronous inductance machine. The drive of this system can limit maximum torque output.

| ● | 1) Internal Combustion engine. |

| ● | 2) Belt Drive Starter Generator. |

| ● | 3) Clutch. |

| ● | 4) Transmission. |

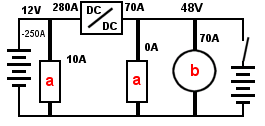

A DC to DC converter is required to "step-down" the voltage from 48V for the 12V system.

Cold start from 12V system:

| ● | A) Electrical load. |

| ● | B) Integrated Starter Generator. |

Under extreme cold weather conditions, the Lithium Ion battery performance may be below optimum efficiency. During such conditions the conventional vehicle battery provides power to the DC to Dc converter, this acts as a step-up transformer for the high voltage system and is used to power the ISG. This is illustrated in the diagram above. Note the reduction in current flow as the voltage is increased.

This advancement in vehicle technology reduces CO2 emissions and increases fuel efficiency, comfort, and performance.

By Damien Coleman, Product Manager/EBI Specialist at Snap-on Diagnostics.

This Toyota Prius had malfunction warning lights illuminated and two faults relating to the High Voltage System stored.

|

Module |

Code |

|---|---|

|

Hybrid Control Module |

P3000 Battery Control System. |

|

HV Battery Control Module |

P0AFA Hybrid Battery System Voltage Low.

|

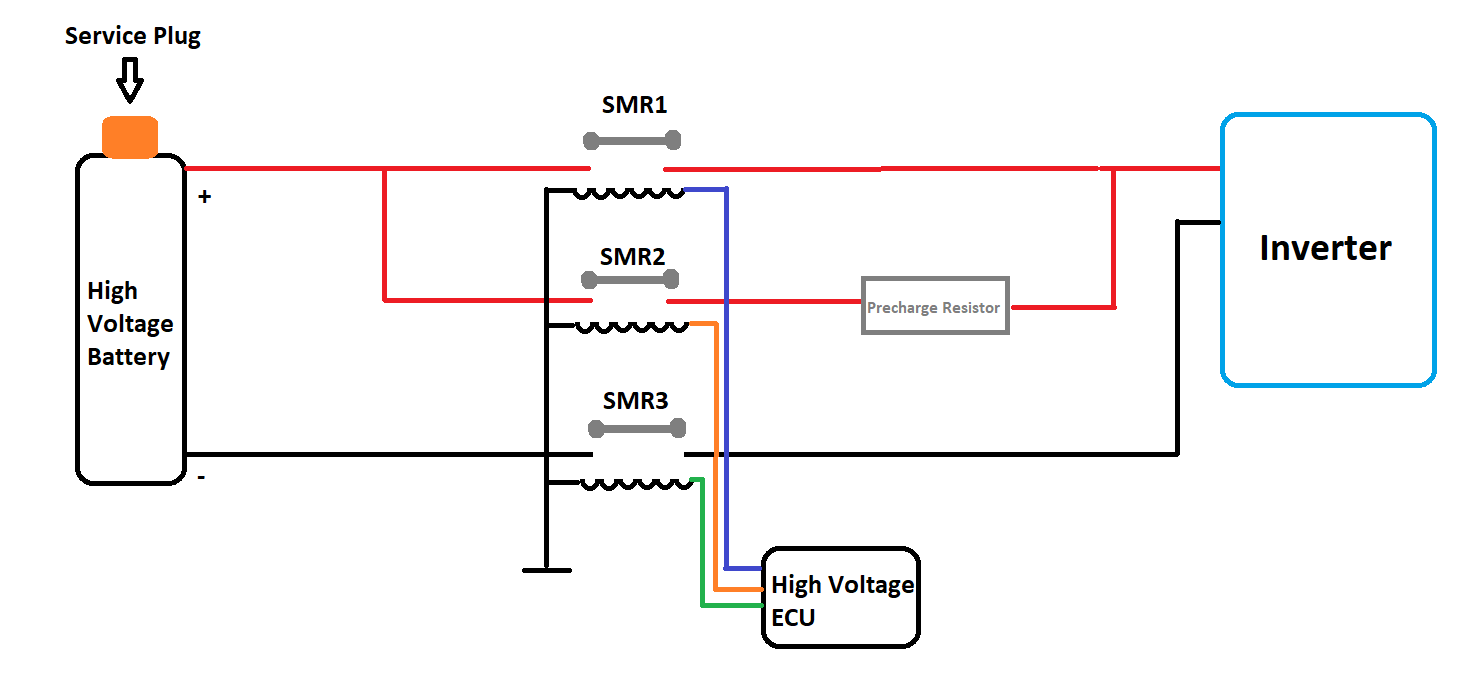

Intermittently the vehicle would not enter “Ready Mode” and the High Voltage System would remain inactive as the high voltage contactors (System Main Relay SMR 1, 2 and 3) were not being switched on by the High Voltage Control Module.

The system has three SMRs.

| ● | SMR 1: Positive Contactor. |

| ● | SMR 2: Pre-charge Contactor. |

| ● | SMR 3: Negative Contactor. |

The Pre-charge function is to limit the initial supply of current from the High Voltage Battery to the Inverter.

Sequence of operation of SMRs:

|

Ready On |

|

||

|---|---|---|---|

|

|

SMR 1 |

SMR 2 |

SMR 3 |

|

Stage 1 |

Off |

Off |

Off |

|

Stage 2 |

Off |

On |

On |

|

Stage 3 |

On |

On |

On |

|

Stage 4 |

On |

Off |

On |

|

High Voltage System Off |

|

||

|

|

SMR 1 |

SMR 2 |

SMR 3 |

|

Stage 1 |

On |

Off |

On |

|

Stage 2 |

Off |

Off |

On |

|

Stage 3 |

Off |

Off |

Off |

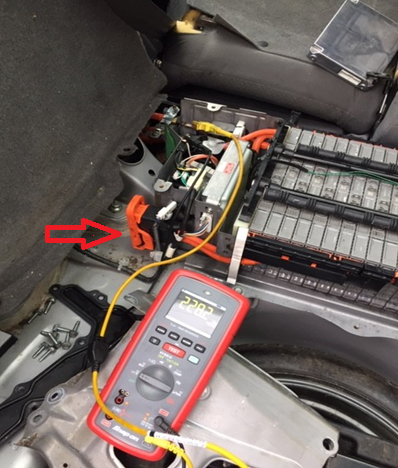

As the High Voltage Battery is located in the luggage compartment and access is difficult, live data was used to monitor the battery voltage for each battery block. The High Voltage battery is made up of 14 x 14.4V blocks. Each block is made up of 2 x 7.2V cells. This equates to a total voltage of 201.6 volts. Anything over 60 volts Direct Current (DC) is considered high voltage. So precautions must be taken when working on such a vehicle, appropriate training, PPE, Insulated tooling, etc.

It must be noted that the High Voltage system must only be worked on by suitably qualified technicians. The High Voltage Service Plug must be removed and the system allowed adequate time to de-energise prior to carrying out work on the system.

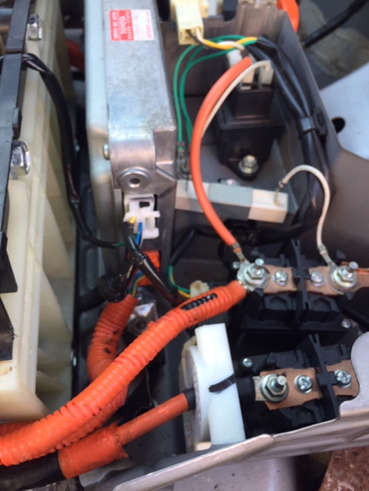

Arrow shows High Voltage Service Plug.

Each battery block has a sensing wire attached to a negative stud which is wired to the High Voltage Control Module.

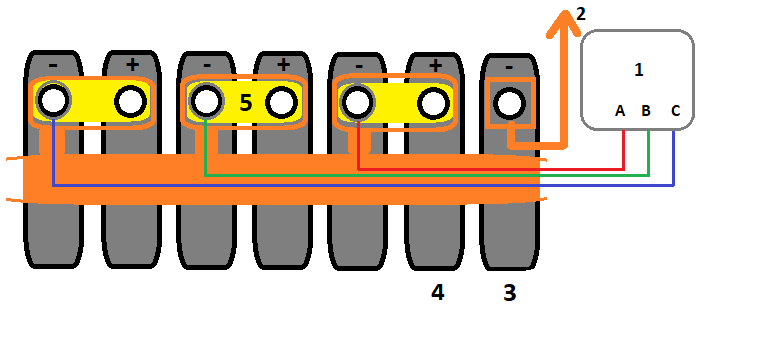

The diagram below shows three blocks as an example.

1. High Voltage Battery Control Module.

2. High Voltage Cable.

3. Cell (Negative Connection)

4. Cell (Positive Connection)

5. Battery Bus Bar.

A. Battery Block 1 sensing wire.

B. Battery Block 2 sensing wire.

C. Battery Block 3 sensing wire.

High Voltage Battery Control Module and Current Clamp (white component) on Negative Wire.

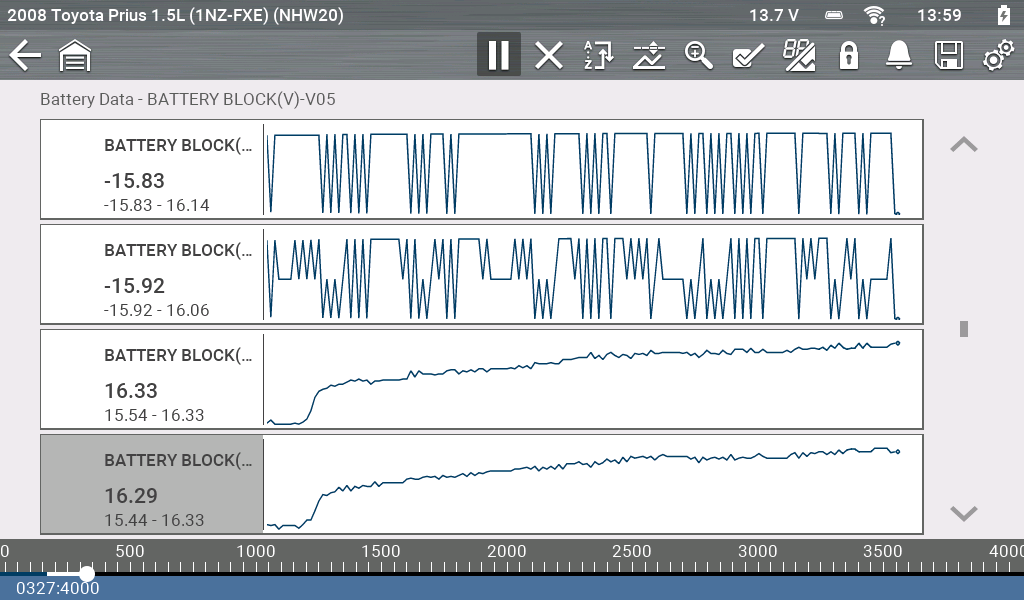

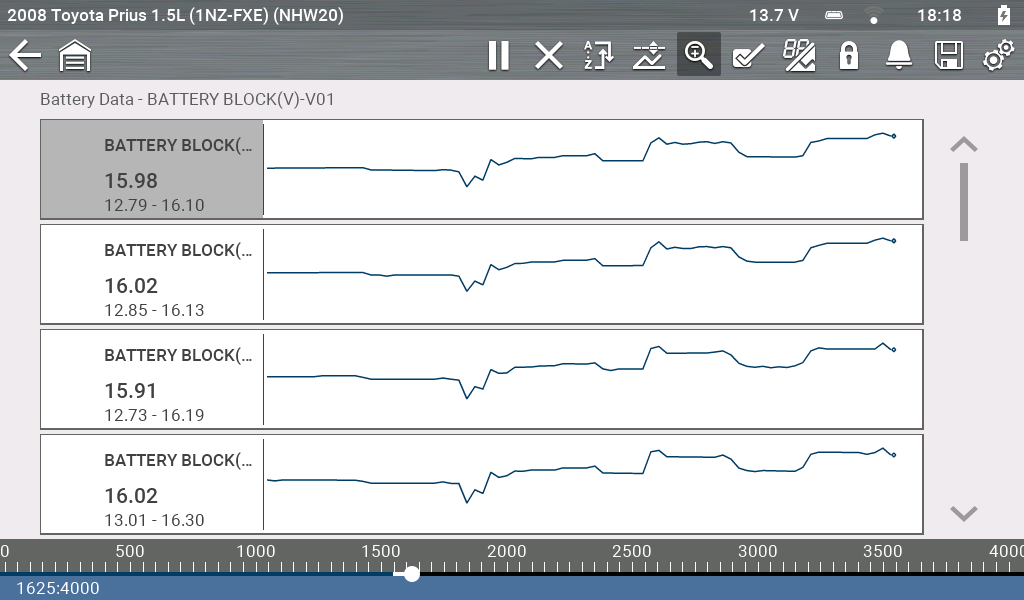

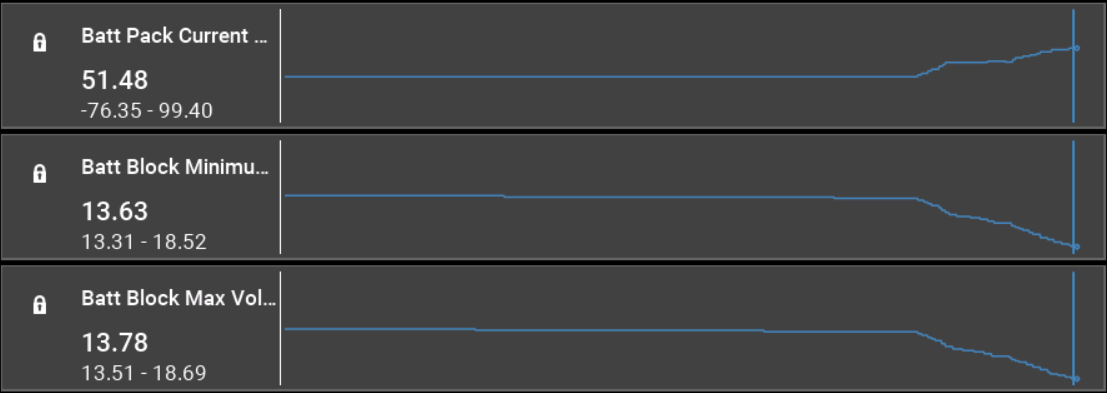

The Screenshot below shows the data observed for four of the fourteen battery blocks.

The first two graphs can be seen to be erratic and not behaving like the other two. The voltage had an irregular cycle between 16 volts negative and 15 volts positive. This condition isn’t possible. So further investigation was required, which required disassembly of the battery casing.

The bus bars connecting the battery cells were found to be corroded so were removed and cleaned. The wiring and connections associated with the battery block sensing circuits were also inspected and cleaned.

Once the system was reassembled and powered up the fault was found to still be present. Next the connections on the High Voltage Battery Control Module were inspected. It was noted that three of the pins on the module were badly corroded.

This module was replaced and the fault codes cleared. The live data now displayed the correct voltage of each battery block.

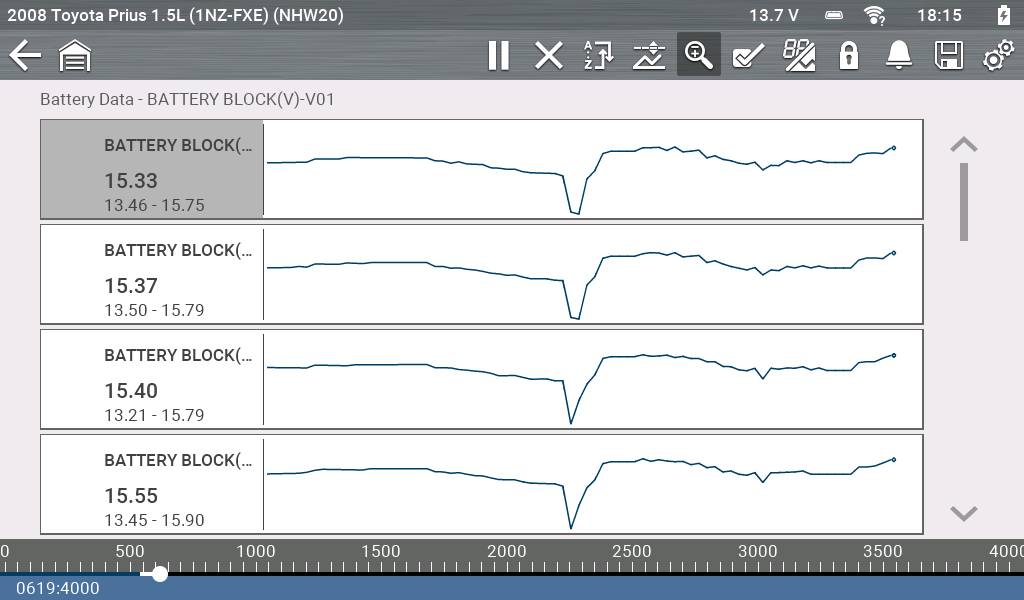

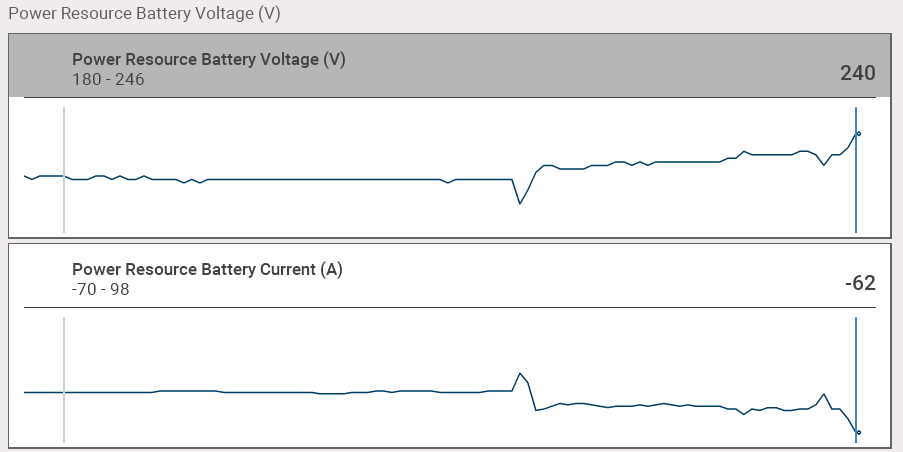

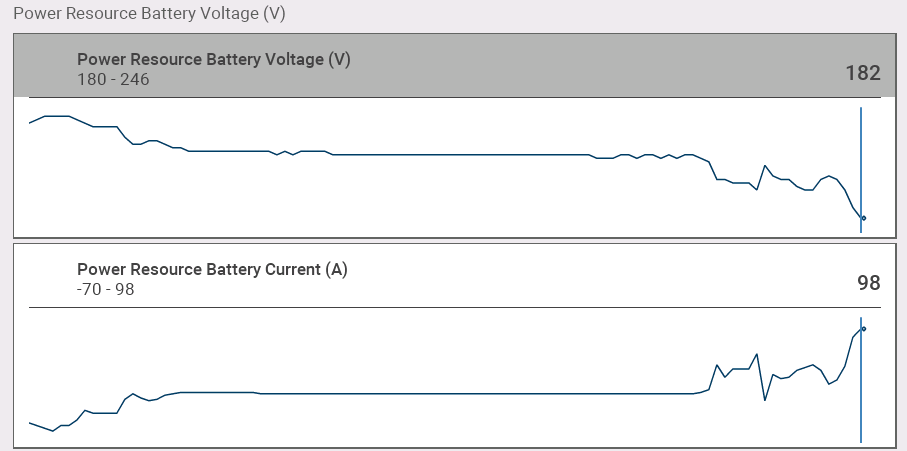

The image above shows the voltage for four battery blocks under hard acceleration, this results in noticeable voltage drop on each block. All fourteen blocks should return a similar voltage under all conditions, full electric mode, hard acceleration and regenerative braking.

The image above shows the voltage for four battery blocks under regenerative braking, this results in voltage increase on each block.

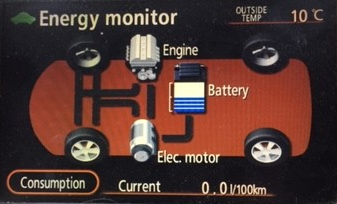

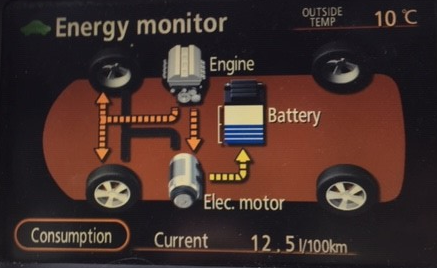

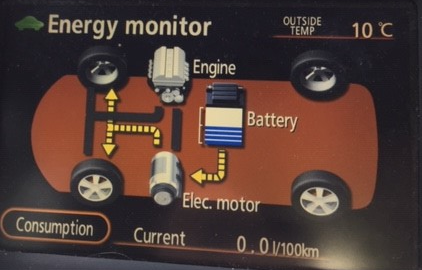

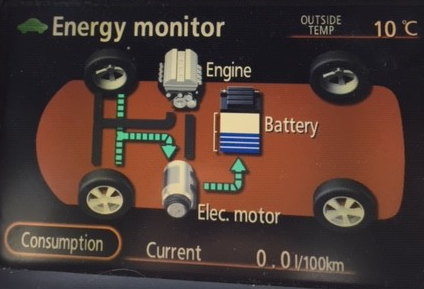

The Prius information display shows the driver the current driving mode through the Energy Monitor which is helpful for fault finding. See images below:

Vehicle Stationary with engine off.

Normal Driving – ICE operating.

Vehicle operating in full electric mode.

High Voltage Battery being charged through Regenerative Braking.

Monitoring High Voltage Battery Condition

While road-testing the vehicle we can check the condition of the High Voltage Battery under certain operating conditions.

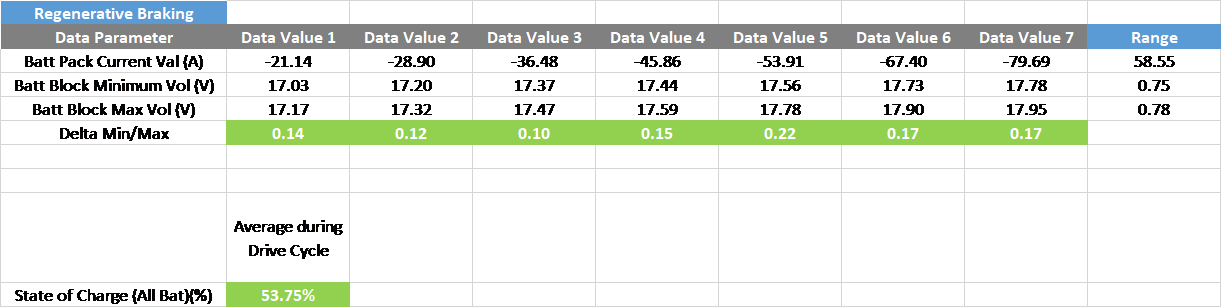

Regenerative Braking

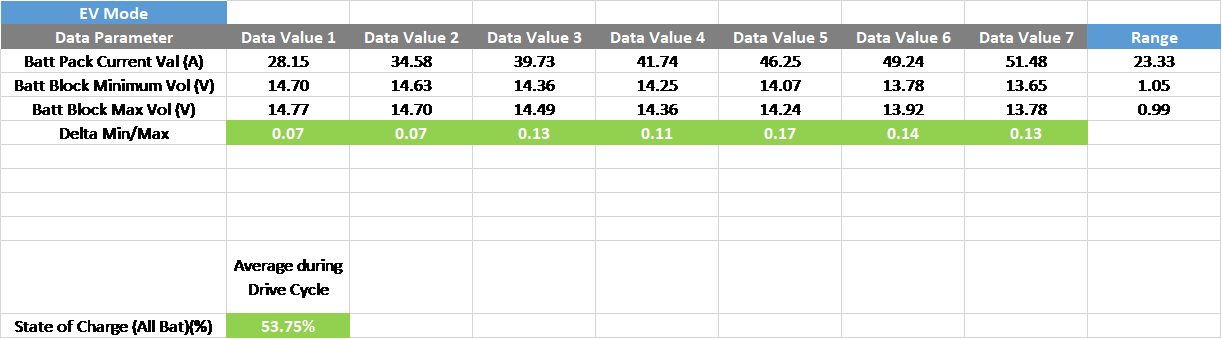

EV Mode

During this test we are looking for a difference of no greater than 0.3 volts between any of the battery blocks under load.

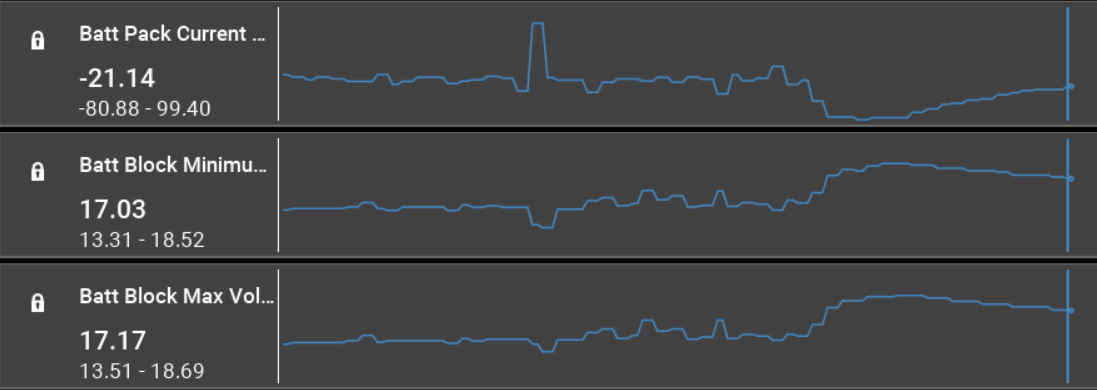

The image below shows the relationship between current and voltage under both conditions.

Regenerative Breaking

EV Mode

After road-testing the vehicle and carrying out a Post Scan with the diagnostic tool, the vehicle was returned to the customer.